NCHRP 12-124: Design of Stud Shear Connectors in Composite Steel Bridges

NCHRP 12-124: Design of Stud Shear Connectors in Composite Steel Bridges

PI: Gary S. Prinz (University of Arkansas) Co-PIs: Matt Hebdon (UT Austin), Tom Murphy (Modjeski and Masters)

Funded By: National Academy of Sciences, National Cooperative Highway Research Program (NCHRP)

Overview: Understanding the mechanisms of bearing, adhesion and friction shear transfer at the steel-concrete interface of composite bridge girders is essential for efficient proportioning of headed shear connectors (or studs). Code provisions for estimating stud demands currently neglect friction and adhesion shear transfer between the concrete slab and steel girder, instead assuming all load transfer occurs through bearing between the studs and concrete deck. While this approach may be reasonable for fully-composite strength limit-state calculations, recent exploratory experimental research and existing analytical research suggests it is likely overly conservative for stud fatigue estimations where service-level loads on individual studs are considered.

This project will investigate shear transfer load-paths in composite girder systems, focussing on understanding the separate roles that concrete adhesion, friction, and shear stud bearing play in load transfer at the steel-concrete interface. The project will couple advanced analytical simulations with creative component-level experiments, system-level experiments, and unique field instrumentation/monitoring to isolate and understand shear transfer mechanisms in composite girders.

Experimental Validation of Special Moment Frame (SMF) Roof-Level Connections

Experimental Validation of Special Moment Frame (SMF) Roof-Level Connections

PI: Gary S. Prinz; Co-PI: Morgan Broberg;

Research Collaborator: Paul W. Richards (BYU)

Funded By: American Institute of Steel Construction (AISC)

Overview: Since 1994, all SMF connections have required experimental tests to confirm that they can accommodate 0.04 rad inelastic drift prior to significant strength degradation. Connection tests that have been conducted to date do not directly reflect roof joints. This research project aims to verify special moment frame (SMF) rooftop connection performance during seismic events through full-scale experimental testing and validated finite element simulations. Experiments will include both one-sided and two-sided SMF rooftop connections. Typical roof beam sizes will be used for the experiments (W27× and shallower) and will include both RBS and WUF-W connections.

Stress-Strain Analysis of BCSA Cement for Structural Applications

Stress-Strain Analysis of BCSA Cement for Structural Applications

PI: Cameron Murray

Funded By: ACI Foundation – Concrete Research Council

Overview: The primary objective of this work is to develop an appropriate value of ultimate compression strain for BCSA cement concrete. The research will also investigate the stress distribution in BCSA concrete at the nominal moment capacity. Finally, axial compressive stress-strain response will be measured for BCSA concrete at different ages. These results will promote confidence in the structural performance of BCSA cement concrete and will also develop new information that can be used to design structures with BCSA cement more efficiently. This work can be an example for investigating flexural performance of other alternative cements.

ARDOT TRC 2203: Low Shrinkage Concrete Mixtures for Arkansas

ARDOT TRC 2203: Low Shrinkage Concrete Mixtures for Arkansas

PI: Cameron Murray

Funded By: Arkansas Department of Transportation

Overview: While most bridge decks in Arkansas perform adequately over their design life, early-age shrinkage cracking is a recurring issue in some bridges that can lead to compromised durability. Shrinkage cracks may lead to serious deterioration such as rebar corrosion and freezing and thawing damage. This shrinkage can be reduced by changing the mixture design or materials, improving construction procedures, and changing structural design parameters.

The objectives of this study are two-fold:

1) Determine the effect of various Arkansas coarse aggregates on the drying shrinkage in standard bridge deck mixtures, and

2) develop a low-shrinkage concrete specification modeled on other state specifications tailored to Arkansas materials.

Steel Seismic Systems with Architectural Flexibility: Seismic Performance of Non-Orthogonal SMF Beam-to-Column Connections

Steel Seismic Systems with Architectural Flexibility: Seismic Performance of Non-Orthogonal SMF Beam-to-Column Connections

PI: Gary S. Prinz

Funded By: American Institute of Steel Construction (AISC) – Milek Fellowship

Overview: The selection of an appropriate seismic steel system (braced frame, moment frame, shear wall, etc.) is often influenced by architectural considerations. Moment frame configurations offer the most architectural flexibility, but are limited by code prequalification requirements that provide limited guidance for the use of non-orthogonal (skewed) beam-column connection geometries. Such architectural constraints often challenge structural design approaches and sometimes limit the competitiveness of steel as a construction material. As building functions continue to evolve, future design approaches must be flexible enough to accommodate architectural forms that deviate from traditional rectangular framing.

This Milek fellowship project focuses on developing comprehensive seismic design guidelines for skewed SMF RBS moment connections. This involves both full-scale experimental testing and detailed parametric finite element analyses. The effectiveness of RBS design procedures for limiting fractures near the beam-column connection welds of skewed SMF connections, composite frame slab effects and the effects from column axial loads on column twisting/yielding are investigated under both static-cyclic and dynamic time-history analyses.

ERDC RIDE Phase 1 & 2: Development of a Prototype Expedient Gap Crossing

Task PI: Cameron Murray, Co-PI: Gary S. Prinz

Funded By: US Army Corps of Engineers, ERDC

Overview: This project is related to the fast deployment and repair of military infrastructure and involves developing a rapidly deployable bridge concept that could be utilized by a small team of near front-line soldiers. It involves the design, analysis, and fabrication of a deployable gap crossing (bridge), as well as structural verification testing of a developed prototype. The final deliverable is expected to be a parts list, assembly schedule, deployment protocol, and executed prototype of an easily deployable gap crossing for gaps up to 25 feet.

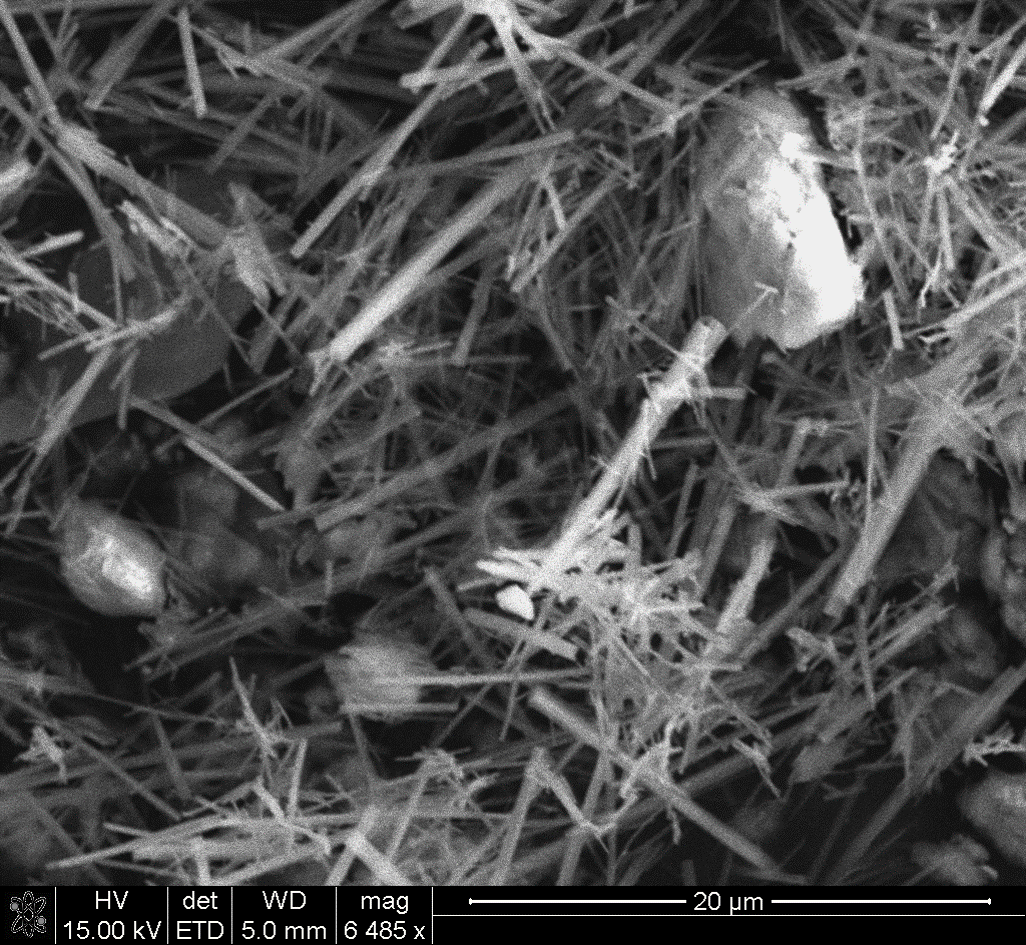

BAA 20 – 124: Advanced Concrete Research and Development for Military Applications

BAA 20 – 124: Advanced Concrete Research and Development for Military Applications

PI: Cameron Murray Co-PIs: Gary S. Prinz, Richard Coffman, Micah Hale

Funded By: Engineering Research and Development Center – GSL

Overview: The goals of this project are to develop alternative testing and mixture design solutions to military infrastructure problems related to concrete. This includes developing concrete mixtures with alternative cements for a variety of applications, developing new ASR mitigation strategies and test methods, and creating new self-stressing UHPC mixtures. The work in this project is divided into 5 tasks which involve multiple researchers in the Department of Civil Engineering at the University of Arkansas.

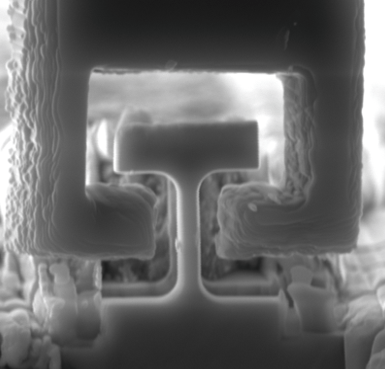

CAREER: A Micro-Mechanics Based Approach to Ductile Fracture Simulation in Additively Manufactured Steels for Seismic Structural Fuse Design:

CAREER: A Micro-Mechanics Based Approach to Ductile Fracture Simulation in Additively Manufactured Steels for Seismic Structural Fuse Design:

PI: Gary S. Prinz

Funded By: US National Science Foundation (NSF); Award Number: 1751699

Overview: Emerging AM technologies (such as 3-D metal printing) are promising for performance-based optimization of steel systems, as they can accommodate highly irregular component designs through highly controlled weld-free geometry formation. However, in order for AM steel parts to transition to functioning components in structural steel systems, the ability to predict damage limit states, such as ductile fracture and low-cycle fatigue, is needed. Existing ductile fracture models lack the ability to accurately capture fracture processes in AM steel alloys due to the complex micro features formed during fabrication. This research aims to characterize the fundamental processes driving ductile fracture in AM steel alloys through nano-mechanical testing and develop models for predicting macro-scale fracture behavior in seismic structural fuse components.

Development of Rapid Setting Soil-Cement Mixture Designs and Performance Testing

Development of Rapid Setting Soil-Cement Mixture Designs and Performance Testing

PI: Cameron Murray Co-PI: Michelle Bernhart-Barry

Funded By: Maritime Transportation Research and Education Center (MarTREC)

Overview: This project builds upon findings from a previous MarTREC project that proved that BCSA cement could be applied to soil-cement mixing (in place of portland cement), speeding up strength gain significantly. The proposed work would narrow down the design and appropriate use of this material, developing mixture proportioning guidelines and investigating its durability with an emphasis on its use in waterway applications (e.g., levee construction and repair, slope protection, erosion protection, seepage reduction). In addition to standard soil and soil-cement properties determination, strength testing, freeze-thaw testing, wetting and drying testing, permeability testing, and erosion testing will be performed. The result will be new guidance on how to effectively use BCSA soil cement for rapidly deployable, long lasting repairs to soil structures. This knowledge could also be used any time faster construction of stabilized soil structures is needed.